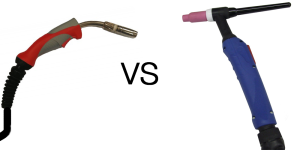

MIG and TIG welders both use an electric arc to make the weld. MIG Welding uses a continuously feeding wire and TIG welding you use long welding rods and slowly feed them into the weld puddle.

MIG Welders vs TIG Welders

MIG welding is generally considered the easiest to learn compared to learning how to TIG weld. The technical names for these are metal inert gas (MIG), and tungsten inert gas (TIG).

A MIG welder operates with a continuously feeding spool of welding wire that fuses the parent metals together. You can weld a variety of materials such as mild steel, stainless steel and aluminium.

A TIG welder on the other hand is more commonly used for your thinner gauge materials. Items that are more often made with this process are things like kitchen sinks and tool-boxes. The biggest benefit in comparison to MIG is that you can get your power down really low and not blow through the metal.

The main difference between MIG and TIG welding is that one method uses a continuously feeding electrode and is a very fast way of putting down welds. The other way is a much more fine and delicate welding technique.

The most versatile machine is the TIG welder as you can weld many different types of metals. The downside is that it is very slow. For anybody wanting to do some welding at home your better choice of machine to buy would have to be the wire feeding MIG welder.

WIRS offer a comprehensive collection of both MIG welders and TIG welders that are available at our three branches in Wolverhampton, Stoke and Shrewsbury. If you need anymore information on the difference between MIG welders and TIG welders give our head office a call on 01902 712525.